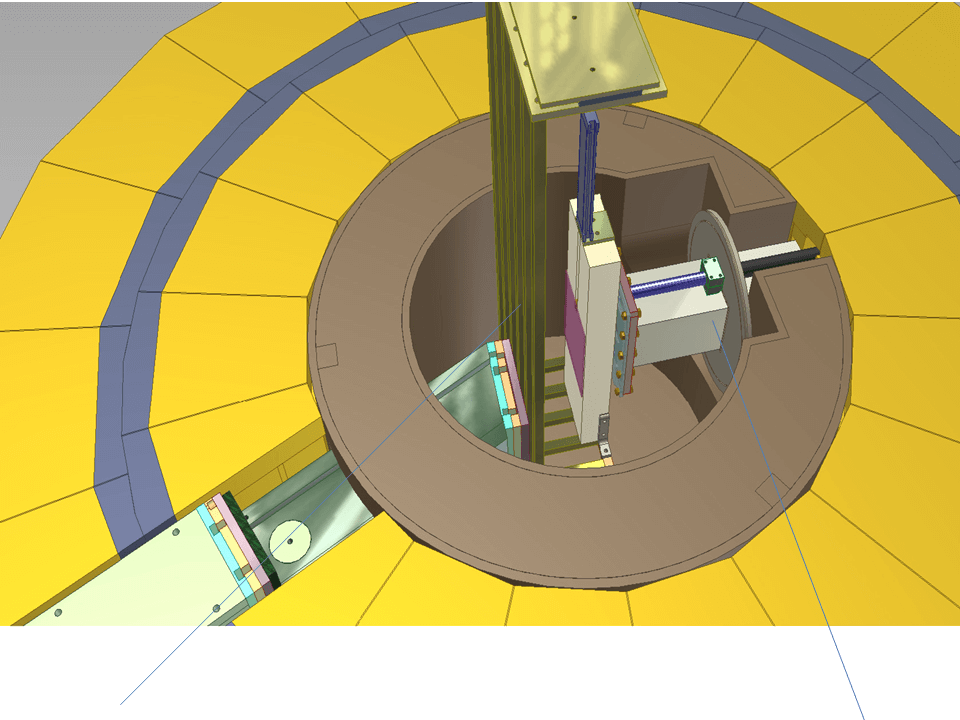

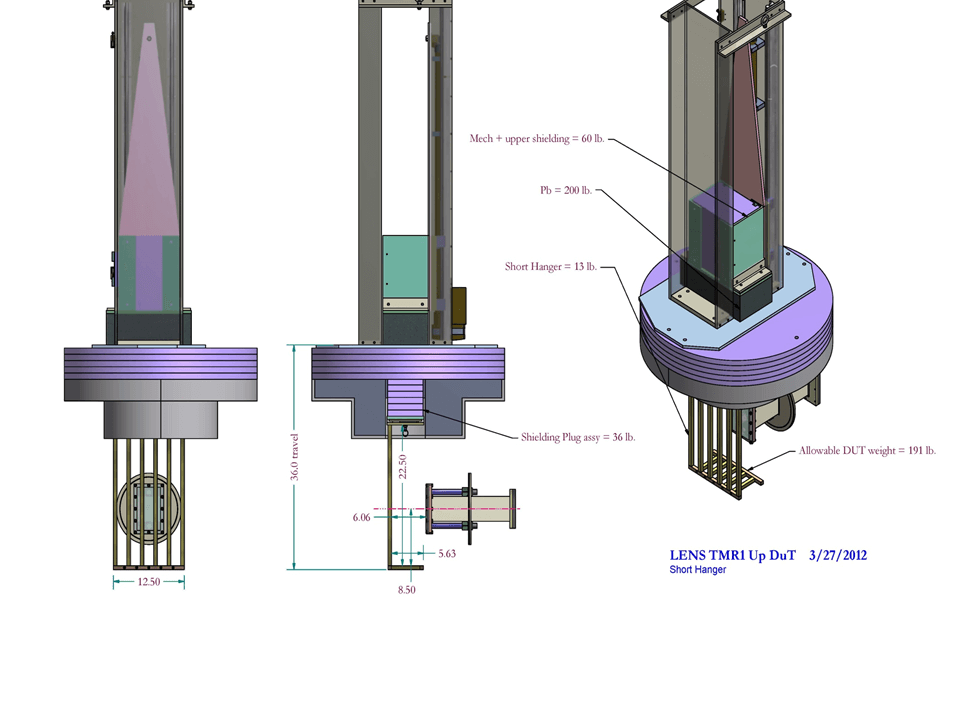

Device testing is conducted in the target station utilizing a mechanized carrier to lower parts into the neutron beam produced by protons on a beryllium target: Effective DUT area is 30cm wide by 56cm high by 14cm deep.

Provisions for device control cables to be connected to the part under test, if required, allow live testing and monitoring of the part: Inside the irradiation vault, 15m long cable is required and neutron dose is approximately 10mrem/hr: Outside the irradiation vault, 120m long cable is required and neutron dose is approximately 1mrem/hr.

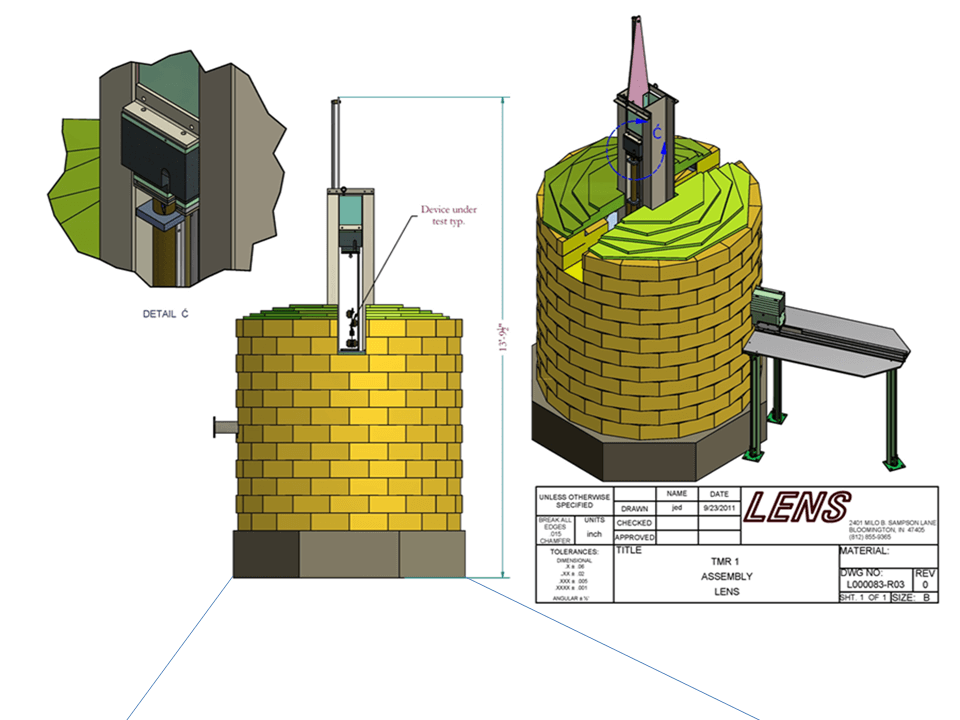

The target station is a cylinder composed of three major components. The first is the beryllium target assembly required for production of neutrons utilizing the 13MeV proton beam from the accelerator. The second is the primary decoupling shielding material containing borated polyethylene blocks. Third are the lead and borated polyethylene bricks to limit exposure of testing equipment and other devices monitoring the Device Under Test.